Development mechanism of thermodynamically stable, thin and protective oxide scales formation at high temperatures in pure water steam on the alloys based on Fe and Ni structures with high chromium content.

Project schedule

The first stage of testing will include thermodynamic predictions of phase formation under selected test conditions available software at Foundry Research Institute (2015 – 2016).

In the second phase of the project, high-temperature tests will be performed by means of long-term exposures of the samples in pure steam atmosphere at two temperatures: T = 700, 750 and T = 800 ºC for 3000 hours (measured by weight at 250 hours) – (2015 – 2017).

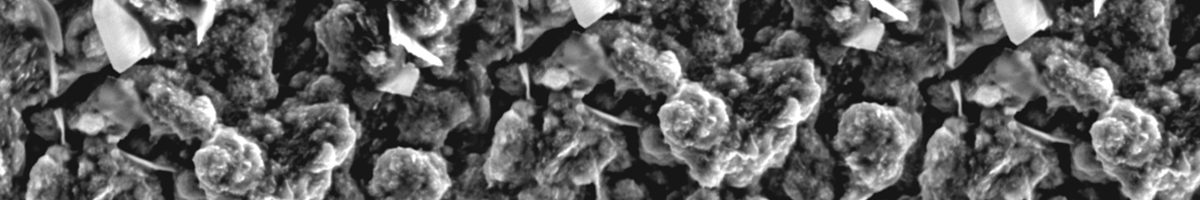

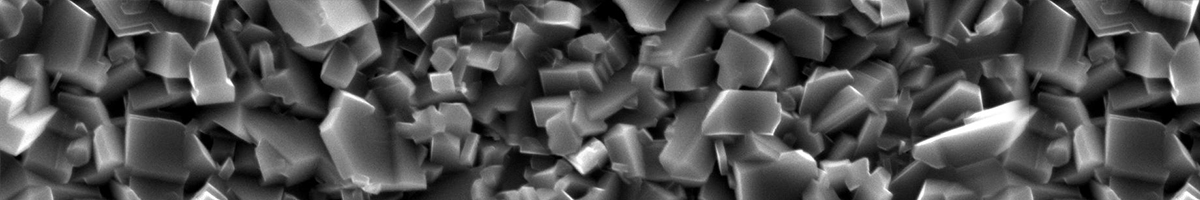

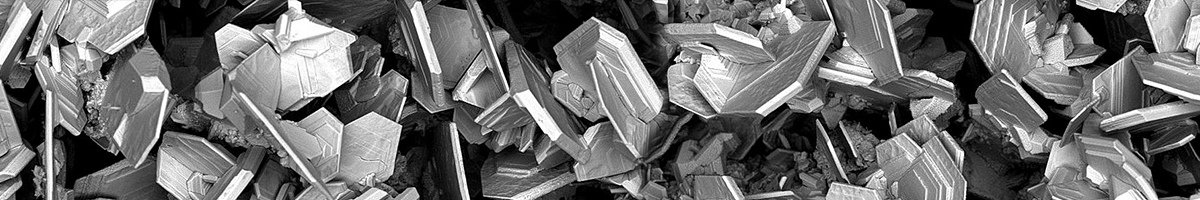

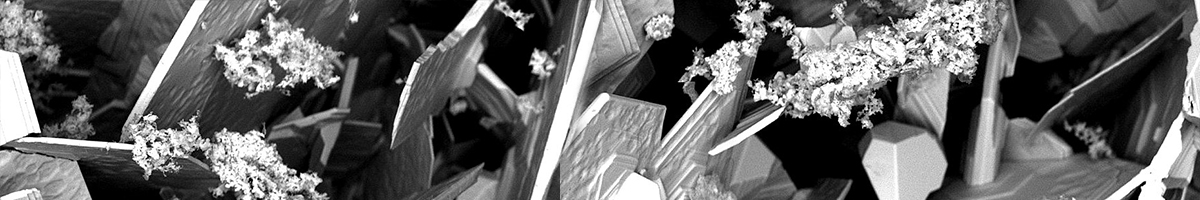

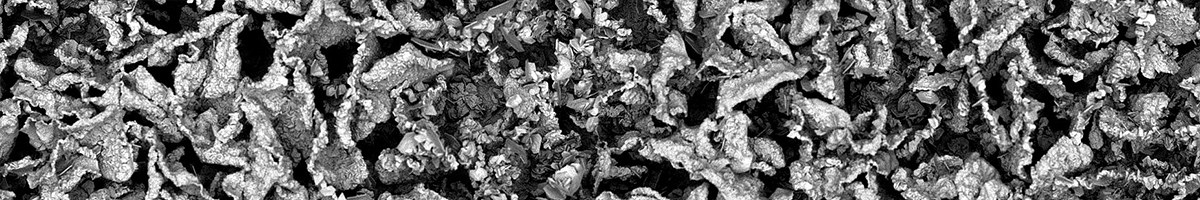

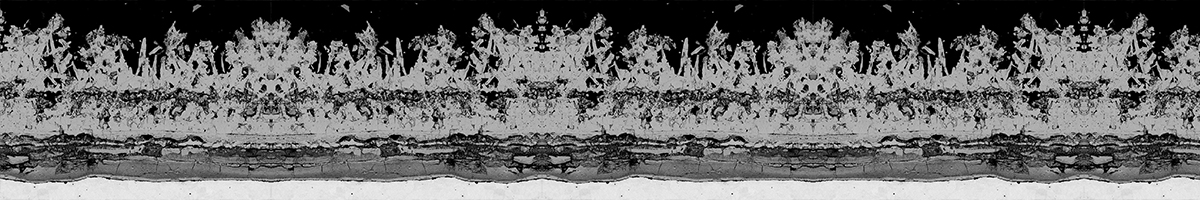

The third stage of the research includes the studies using macro and micro analytical instruments such as digital camera coupled with macro lens. Micro analyses will be perfomed using scanning electron microscope (SEM) coupled with energy x-ray dispersive spectrometry (EDS). Furthermore, the samples will be investigated through identification of phases, size of crystallites and stresses formed during scale growth under steam oxidation using x-ray diffractometer (XRD) – (2015 – 2017).

In the fourth stage of the project, the results received from the high temperature steam oxidation tests will be used to calculate metal loss of the exposed materials. (2017)

The fifth stage of the project is dedicated for neural network modelling, in order to predict kinetic behaviour of the alloys exposed at high temperatures (2017)

The aim of the project is to explain development mechanism of thermodynamically stable, thin oxide scales formed during steam oxidation of Fe and Ni based alloys with high content of Cr (> 20 wt%). High temperature mechanism will be explained based on steam oxidation exposures of highly alloyed steels in close loop system at T = 700, 750 and T = 800 oC for t = 3000 hours. Based on the research performed within the timeframe of this project, the following objectives are stated:

1. To investigate the mechanism by means of high temperature long term steam oxidation tests, at T = 700, 750 and T = 800 oC for 3000 hours in pure water steam under p = 1 bar

2. To assess metal loss of the exposed alloys, based on high temperature exposures in pure water steam

3. To assess the influence of chemical composition on Fe and Ni based alloys on the development of thermodynamic stable, thin oxide scales during high temperature steam exposures.

4. To use neural network modelling as a tool for kinetic prediction of mass change of the exposed materials

NCN reference: 2014/13/D/ST8/03256

Organisation: Foundry Research Institute (FRI) in Krakow

Department: Centre for High Temperture Studies

Principal investigator: Doctor, Dudziak T

NCN Research Topic Classifications: Fundamental Research

Starts: 21-01-2015

Ends: 22-01-2018

Value (PLN): 594 870,0

Development mechanism of thermodynamically stable, thin and protective oxide scales formation at high temperatures in pure water steam on the alloys based on Fe and Ni structures with high chromium content

Materials included in the research:

Cr rich austenitic stainless steels (SS): HR3C, 309S, 310S

Ni based alloys: Haynes 230, alloy 617, alloy 263, Haynes 282

Principal investigator kindly appreciate SANDMAYER STEELS and HAYNES INTERNATIONAL for the materials delivered to high temperature steam oxidation tests in this project.